CHECK METALLIC

JF METAL

March 2024

April 2025

-

-

Diogo Ribeiro

Ricardo Santos, Rodrigo Falcão Moreira, Rosário Oliveira, João Ventura, Jorge Magalhães & Óscar Moreira

The CHECK METALLIC project, developed in partnership between the iBuilt team at ISEP and the company JF METAL, aimed to create an automated methodology for precision geometric control of steel structures, with a particular focus on the assembly phase, ensuring compliance with the tolerances required by the NP EN 1090-2:2020 standard.

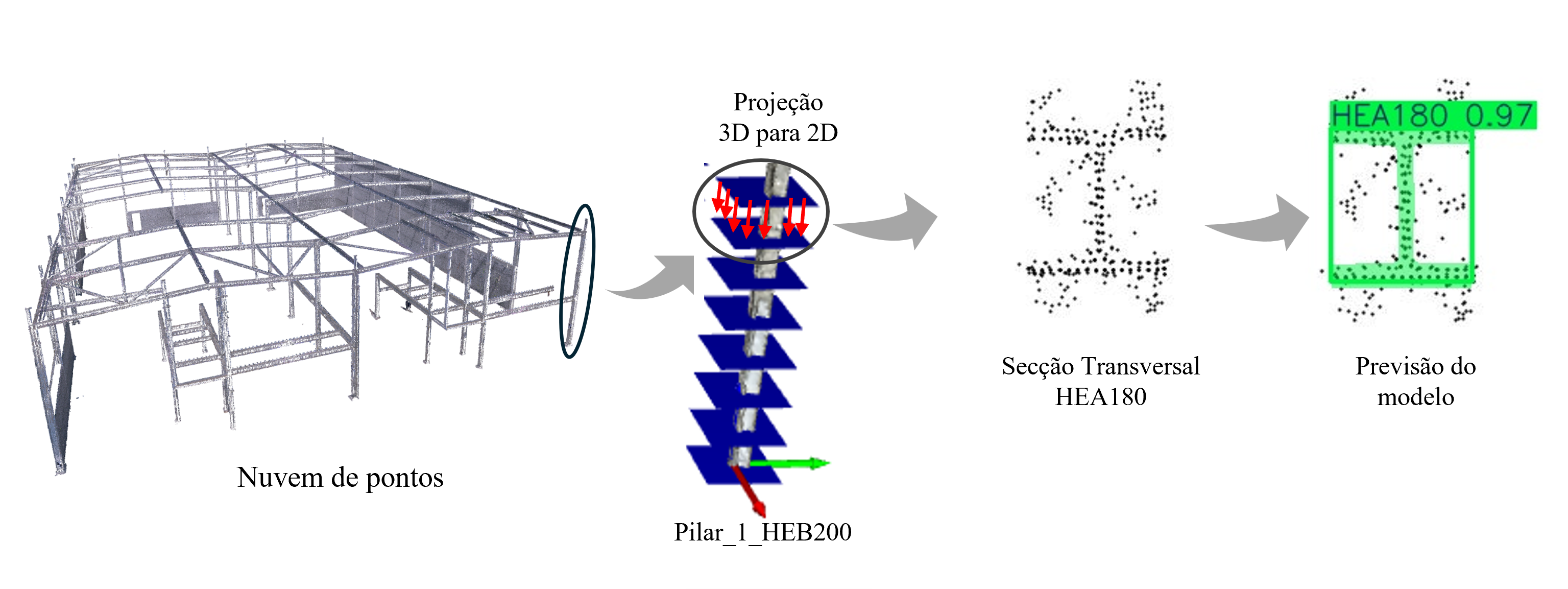

Different advanced technologies were explored, from 3D point cloud surveys using digital technologies through the combination of photogrammetry (using UAVs) and Terrestrial Laser Scanning (TLS), enabling the creation of accurate digital models of the real state of the structure (As-Is Model). These models are compared with the design models (As-Design Model), allowing detailed analysis of possible deviations and discrepancies.

One of the main innovations of the project was the use of the YOLOv8 architecture, which enabled the automatic identification of cross-sections of structural elements in images, through segmentation and automatic detection techniques with Oriented Bounding Boxes (OBBs).

The CHECK METALLIC methodology can be summarized in three main steps: